Ultrasound Pretreatment Improved the Flowability and Water Sorption Properties of Micellar Casein Concentrate

Recently, the Dairy Processing Technology and Quality Control Research Team, Institute of Food Science and Technology, Chinese Academy of Agricultural Sciences (IFST, CAAS), has found that ultrasound pretreatment can greatly improve the flowability of powders by increasing particle size and changing surface composition. The relevant research results were published in the journal of Food Chemistry with the title “Ultrasound pretreatment prior to spray drying improve the flowability and water sorption properties of micellar casein concentrate.”

Ultrasound (US) is considered a nonpolluting and nonionizing form of energy generated by mechanical vibrations that produce sequential compression and rarefaction waves in a liquid and has been applied to dairy research in microorganism inactivation and components extraction from cells or tissues, enzymatic activity acceleration, or inactivation and emulsification improvement. Micellar casein concentrate is a high casein dairy powder with notable nutritional and functional properties for high-value commercial applications such as infant and sports nutrition products. To extend its potential application, the latest research on the application of US to high-protein powder is mainly focused on protein modification to improve its solubility, foaming properties, emulsification, and gel properties. However, bulk processing and application of high protein milk powders are often challenging and strongly affected by their poor flow properties. In transporting, handling, and processing operations, powder flow properties are crucial, as changes in flow properties can result in poor quality or stoppages in processing. The main objective of this research is to evaluate the effect of ultrasound treatment on powder flow and moisture sorption properties of micellar casein concentrates.

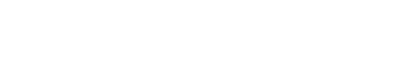

Results revealed that micellar casein concentrate (MCC) produced from skim milk microfiltration was sonicated at the energy intensity of 0 (control), 47 J/mL (S-2000), 62 J/mL (S-3000), and 76 J/mL (S-4000). US pretreatment significantly increased the average particle size from 82.46 μm to 100.73 μm and reduced the surface fat content from 19.2% to 13.8%, resulting in decreased basic flow energy, and cake energy and cohesion. Besides, the US-treated samples showed a relatively poor ability to acquire moisture from the atmosphere than the control. Protein structure analysis showed that α-helix decreased with enhanced US power, while β-sheet and surface hydrophobicity increased, implying hydrophobic groups were exposed and water sorption rate was impeded. To sum up, US pretreatment can improve the powder flow and potentially reduce the negative effect of cake formation at high humidity.

This work was supported by the National Key R&D Program of China (2021YFD2100700, 2021YFD2100703, 2021YFD2100702), Ningxia Key R&D Program (2021BEF02022), Inner Mongolia Science and Technology Program (2021GG0368).

Fig. a: Basic flow energy and SEM images of the un-sonicated and sonicated micellar casein concentrate samples

b: Compressed bulk density (CBD) and compressibility of the un-sonicated and sonicated micellar casein concentrate samples

c: Total cake energy and cohesion of the un-sonicated and sonicated micellar casein concentrate samples. d: Protein and lipids(fat) content in the particle surface of the un-sonicated and sonicated micellar casein concentrate samples

Link to the paper: https://doi.org/10.1016/j.ultsonch.2022.106049

By Wang Junna (wangjunna@caas.cn)

-

Apr 18, 2024Opening Ceremony of the Training Workshop on Wheat Head Scab Resistance Breeding and Pest Control in Africa Held in CAAS

Apr 18, 2024Opening Ceremony of the Training Workshop on Wheat Head Scab Resistance Breeding and Pest Control in Africa Held in CAAS -

Apr 03, 2024IPPCAAS Co-organized the Training Workshop on Management and Application of Biopesticides in Nepal

Apr 03, 2024IPPCAAS Co-organized the Training Workshop on Management and Application of Biopesticides in Nepal -

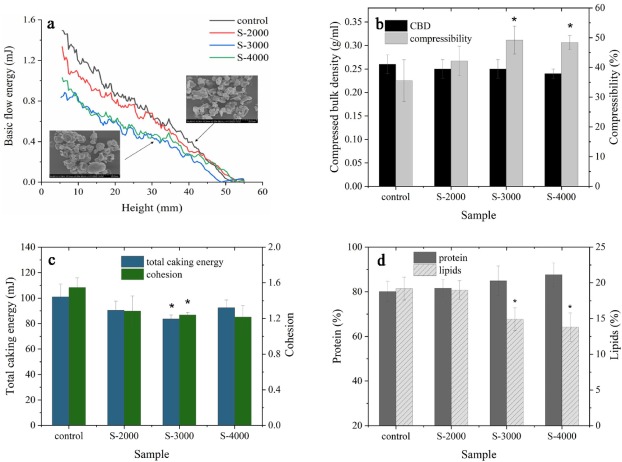

Mar 28, 2024Delegation from the School of Agriculture and Food Science of University College Dublin, Ireland Visit to IAS, CAAS

Mar 28, 2024Delegation from the School of Agriculture and Food Science of University College Dublin, Ireland Visit to IAS, CAAS -

Mar 25, 2024Director of World Food Prize Foundation visited GSCAAS

Mar 25, 2024Director of World Food Prize Foundation visited GSCAAS -

Mar 20, 2024Institute of Crop Sciences (ICS) and Syngenta Group Global Seeds Advance Collaborative Research in the Seed Industry

Mar 20, 2024Institute of Crop Sciences (ICS) and Syngenta Group Global Seeds Advance Collaborative Research in the Seed Industry