分享到

Energy Policy Tools for Agricultural Residues Utilization for Heat and Power Generation

Cane trash could viably substitute fossil fuels in heat and power generation projects to avoid air pollution from open burning and reduce greenhouse gas (GHG) emission. It is competitive with bituminous and other agro-industrial biomass. Recently, the research group, led by CAAS Vice President Dr. TANG Hua-jun, considered in both dimensions of the utilization system and competitive utilization systems for more realistic potential evaluation of cane trash utilization for heat and power generation.

The research showed that using cane trash for heat generation project could provide a higher reliability and return on investment than power generation project. The heat generation project could be viable (Financial Internal Rate of Return, FIRR = 36–81%) without feedstock subsidy. With current investment and support conditions, the capacity of 5 MW option of power generation project is the most viable (FIRR = 13.6–15.3%); but 30 MW, 1 MW and 10 MW options require feedstock subsidy 450–1100 Baht/t-cane trash to strengthen financial viability. Furthermore, the revenue from carbon credit sales could compensate the revenue from current energy price adder and increases 0.5–1.0% FIRR of power generation project. Using cane trash for 1 MW power generation could reduce GHG emission 637–861 tCO2eq and avoid air pollutant emissions of 3.35 kg nitrogen oxides (NOx), 0.41 kg sulfur oxides (SOx) and 2.05 kg volatile organic compounds (VOC). Also, 1 t steam generation from cane trash could avoid pollutant emissions of 0.6 kg NOx, 0.07 kg SOx, and 0.37 kg VOC. The potential of cane trash to cause fouling/slagging as well as erosion are not significantly different from other biomass, but chlorinated organic compounds and NOx could be higher than bituminous and current biomass feedstock at sugar mill (bagasse and rice husk).

The research concludes that developing heat and power project using such agricultural residues as cane trash tend to be economically feasible for implementation with feed stock subsidy. Also, it is environmentally feasible and satisfies the government’s promotion of alternative energy and discouraging cane trash open burning. Supply cost is the main barrier for using cane trash, it is necessary to develop collecting tools to facilitate cane trash harvest as well as supply chain strategies to overcome this barrier. However, fuel related problems require further study in details to ensure operational reliability and improve the plant efficiency for using cane trash in the future. To this end, some demonstration power projects using cane trash should be initiated before promoting it for commercial use. The more detailed information can be downloaded from the international Journal- Renewable and Sustainable Energy Reviews.

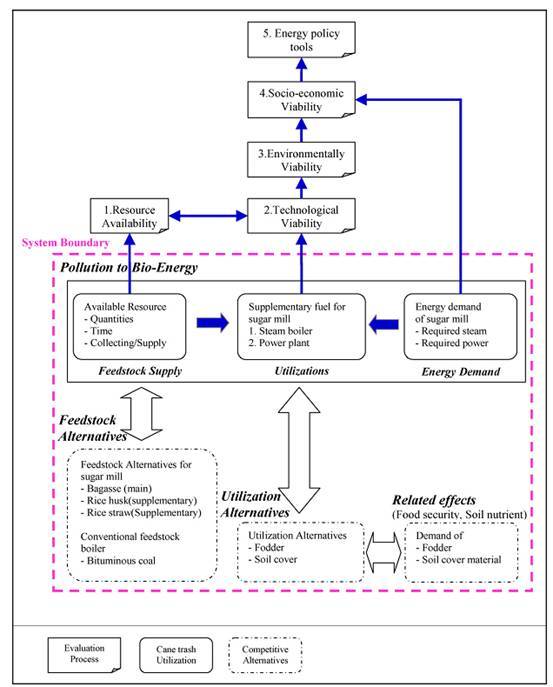

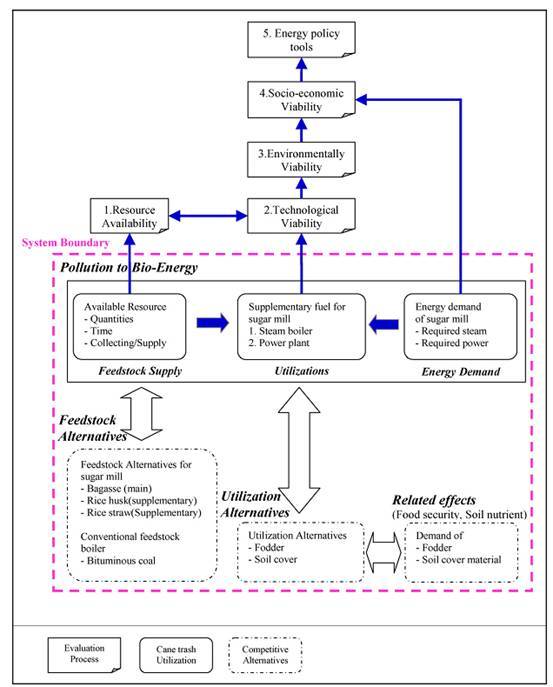

Fig. 1 The flow chart of the research framework. Viability of utilization considers linkage of four aspects, resource availability, technological viability, environmental and socio-economic viability.

The research showed that using cane trash for heat generation project could provide a higher reliability and return on investment than power generation project. The heat generation project could be viable (Financial Internal Rate of Return, FIRR = 36–81%) without feedstock subsidy. With current investment and support conditions, the capacity of 5 MW option of power generation project is the most viable (FIRR = 13.6–15.3%); but 30 MW, 1 MW and 10 MW options require feedstock subsidy 450–1100 Baht/t-cane trash to strengthen financial viability. Furthermore, the revenue from carbon credit sales could compensate the revenue from current energy price adder and increases 0.5–1.0% FIRR of power generation project. Using cane trash for 1 MW power generation could reduce GHG emission 637–861 tCO2eq and avoid air pollutant emissions of 3.35 kg nitrogen oxides (NOx), 0.41 kg sulfur oxides (SOx) and 2.05 kg volatile organic compounds (VOC). Also, 1 t steam generation from cane trash could avoid pollutant emissions of 0.6 kg NOx, 0.07 kg SOx, and 0.37 kg VOC. The potential of cane trash to cause fouling/slagging as well as erosion are not significantly different from other biomass, but chlorinated organic compounds and NOx could be higher than bituminous and current biomass feedstock at sugar mill (bagasse and rice husk).

The research concludes that developing heat and power project using such agricultural residues as cane trash tend to be economically feasible for implementation with feed stock subsidy. Also, it is environmentally feasible and satisfies the government’s promotion of alternative energy and discouraging cane trash open burning. Supply cost is the main barrier for using cane trash, it is necessary to develop collecting tools to facilitate cane trash harvest as well as supply chain strategies to overcome this barrier. However, fuel related problems require further study in details to ensure operational reliability and improve the plant efficiency for using cane trash in the future. To this end, some demonstration power projects using cane trash should be initiated before promoting it for commercial use. The more detailed information can be downloaded from the international Journal- Renewable and Sustainable Energy Reviews.

Fig. 1 The flow chart of the research framework. Viability of utilization considers linkage of four aspects, resource availability, technological viability, environmental and socio-economic viability.

Latest News

-

Apr 18, 2024Opening Ceremony of the Training Workshop on Wheat Head Scab Resistance Breeding and Pest Control in Africa Held in CAAS

Apr 18, 2024Opening Ceremony of the Training Workshop on Wheat Head Scab Resistance Breeding and Pest Control in Africa Held in CAAS -

Apr 03, 2024IPPCAAS Co-organized the Training Workshop on Management and Application of Biopesticides in Nepal

Apr 03, 2024IPPCAAS Co-organized the Training Workshop on Management and Application of Biopesticides in Nepal -

Mar 28, 2024Delegation from the School of Agriculture and Food Science of University College Dublin, Ireland Visit to IAS, CAAS

Mar 28, 2024Delegation from the School of Agriculture and Food Science of University College Dublin, Ireland Visit to IAS, CAAS -

Mar 25, 2024Director of World Food Prize Foundation visited GSCAAS

Mar 25, 2024Director of World Food Prize Foundation visited GSCAAS -

Mar 20, 2024Institute of Crop Sciences (ICS) and Syngenta Group Global Seeds Advance Collaborative Research in the Seed Industry

Mar 20, 2024Institute of Crop Sciences (ICS) and Syngenta Group Global Seeds Advance Collaborative Research in the Seed Industry