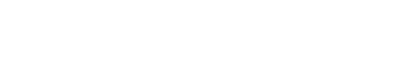

Researchers from IFST revealed the moisture release and quality deterioration of precooked beef during freezing-thawing-reheating processes by integrating multiple microstructure and water distribution visual analysis

Recently, Chinese Food Processing and Equipment Innovation Team of Institute of Food Science and Technology (IFST), Chinese Academy of Agricultural Sciences utilized integrating multiple microstructure and water distribution visual analysis to reveal the moisture release and quality deterioration of precooked beef during freezing-thawing-reheating processes. The research findings were published in the Food Chemistry (IF: 8.5), a JCR Q1 journal in the discipline of food science.

Prepared dishes (semi-finished or finished products made of poultry, livestock, agricultural, and aquatic sources, combined with various auxiliary ingredients and subjected to preprocessing and precooking steps) are becoming popular among the catering industry and domestic consumption due to the advantages of cost control, efficient production, and convenience.

Besides, prepared dishes have the advantages of cutting down the labor force needed and lighten worker's labor intensity, which contributed to alleviating the problems of an aging society. Compared to the traditional cold chain system of raw meat, the supply chain of precooked meat is more complex, which not only has the freezing-thawing process but also includes the reheating process before final consumption.

Results showed that both freezing-thawing and reheating affected water distribution, texture, and color of precooked beef. Although less moisture loss is produced in the freezing-thawing process, the ice formation and melting damaged the muscle fiber structure, which decreased the water-muscle bonding capacity, promoting immobilized water transfer to free water and exists in the interfibrous cavity, and leakage to extra muscular space caused by thermal contraction during reheating process, resulting in greater moisture loss of frozen precooked beef during the reheating process. The thawing process caused muscle extension and water redistribution, leading to greater moisture loss, muscle fiber repeated stretches and contractions, and lipid oxidation during the thawing and reheating processes.

The results of the present study revealed the potential mechanism of moisture loss and structure evolution of precooked beef during the freezing-thawing-reheating sequence. These findings could facilitate our study of precooked meat quality variation in specific cold-hot combination supply chains, which filling the gaps in the industry and generate a useful database to further improve the commercialized production in the prepared dishes industry.

Professor Chunhui Zhang and Xia Li the corresponding author and the GSCAAS-LGg program PhD student Hengxun Lin is the first author. This research was financially supported by the Project of Science Platform of BUA in 2023 (No. BUAPSP202305); Agricultural Science and Technology Innovation Program of Institute of Food Science and Technology, Chinese Academy of Agricultural Sciences (CAAS-ASTIP-G2022-IFST); Taishan Industry Leading Talent Project (Chinese dishes industrial processing quality improvement and industrialization demonstration project).

https://doi.org/10.1016/j.foodchem.2024.140878

-

Oct 23, 2024IPPCAAS Wins the 2024 FAO Achievement Award

Oct 23, 2024IPPCAAS Wins the 2024 FAO Achievement Award -

Oct 23, 2024ICS Hosted the Symposium of China-European Union Nature-based Solutions for Nutrient Management International Cooperation Program

Oct 23, 2024ICS Hosted the Symposium of China-European Union Nature-based Solutions for Nutrient Management International Cooperation Program -

Sep 30, 2024China-Laos Training Workshop on Integrated Management of Major Crop Pests and Diseases Concludes Successfully in Laos

Sep 30, 2024China-Laos Training Workshop on Integrated Management of Major Crop Pests and Diseases Concludes Successfully in Laos -

Sep 26, 2024IARRP's AI project research achievement wins the Excellence Award at the Big Data Expo

Sep 26, 2024IARRP's AI project research achievement wins the Excellence Award at the Big Data Expo -

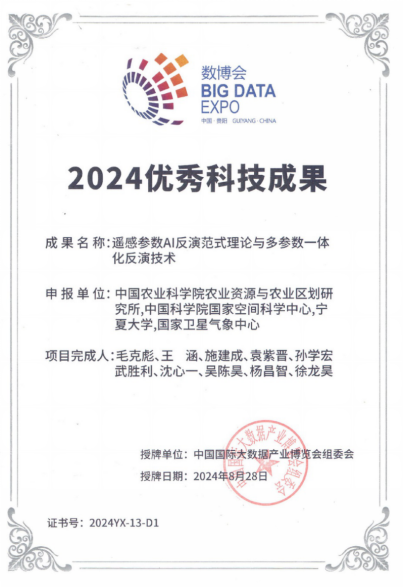

Sep 11, 20242024 International Apicultural Asia Regional Symposium Held in Beijing

Sep 11, 20242024 International Apicultural Asia Regional Symposium Held in Beijing