Chinese Food Processing and Equipment Research Team of IFST reveals the mechanism of CMC-regulated multi-chamber formation to improve the texture of deep-fried batter-coated meat strips

Recently, researchers from Chinese Food Processing and Equipment Research Team of Institute of Food Science and Technology, Chinese Academy of Agricultural Sciences (IFST-CAAS) integrated multiple visual evaluation techniques to reveal the mechanism of anionic carboxymethyl cellulose (CMC) regulating the formation of multi-chamber on the improvement of the texture of deep-fried batter-coated meat strips (BCMSs), and the related research results have been published in the authoritative journal, Food Hydrocolloids (JCR Q1, IF = 12.4). Ying Xu, a PhD student, was the first author, Prof. Chunhui Zhang and Feng Huang serving as co-corresponding authors. This study was supported by the National Key R&D Program of China (2023YFD2100700) and the Science and Technology Innovation Project of the Chinese Academy of Agricultural Sciences (CAAS-ASTIP-2025-IFST-06).

A soft interior texture with a crispy exterior is a critical quality for deep-fried BCMSs. The high-strength gel formed by the hanging paste layer can limit oil penetration by inhibiting moisture loss, thereby reducing the degree of protein thermal denaturation in the center meat strip layer and achieving tenderness retention. However, the retention of moisture hinders the development of crispness. Therefore, maintaining the crispness of the batter layer and the tenderness and juiciness of the meat strips at the same time seems to be contradictory. Crispy exterior and tender interior depend on the adjustment of the gel structure of the deep-fried batter to the chamber, which further controls the migration of water/oil/heat between the medium, crust and core meat. CMC with anions was found that could modify gel structure through electrostatic interaction with starch and gluten in batter. Therefore, it is hypothesized that CMC can compete for gluten-starch binding sites, thereby weakening the increase in gel elasticity caused by gluten-starch interaction.

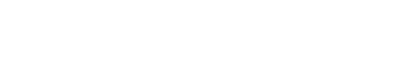

This study was designed to reveal the mechanism by which CMC promotes the formation of a soft texture in the interior with a crispy exterior of deep-fried BCMSs in terms of batter properties, gel structure, heat and mass transfer, chamber formation, and muscle protein denaturation. The results showed that CMC could affect the texture of BCMSs by adjusting the rheological properties of wheat starch-flour blends. The 0.75%CMC-treated batter produced the thickest coating with poor gel stability, making it prone to fracturing and creating large chambers. These chambers allowed more heat and oil to penetrate the core meat, increasing crust crispness but reducing meat tenderness. However, appropriate addition of CMC (0.5%) improved the gel strength and integrity of the fried batter, restricted oil and heat penetration into the meat core, and minimized muscle protein unfolding and re-aggregation, thus preserving meat tenderness. Meanwhile, delayed protein denaturation decreased water migration from the meat to the crust, enhancing crispness.

The information obtained provides scientific guidance for quality control in the industrial production of deep-fried coated meat products.

https://doi.org/10.1016/j.foodhyd.2025.111556

Improvement mechanism of "crispy outside and tender inside" texture of deep-fried BCMSs by adding CMC in appropriate amounts

-

Jun 05, 2025CAAS President Meets New FAO Representative in China

Jun 05, 2025CAAS President Meets New FAO Representative in China -

May 27, 2025Director General of IARRP attends 2025 Global Forum of Group on Earth Observations

May 27, 2025Director General of IARRP attends 2025 Global Forum of Group on Earth Observations -

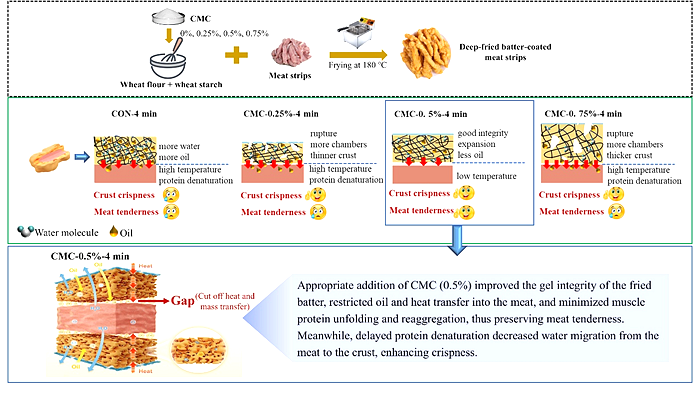

May 20, 2025IPPCAAS Experts Visit Australia to Promote In-Depth China–Australia Cooperation in Plant Biosafety

May 20, 2025IPPCAAS Experts Visit Australia to Promote In-Depth China–Australia Cooperation in Plant Biosafety -

May 20, 2025Opening Ceremony of the Seminar on Modern Breeding and Management of the Vegetable Industry for BRI Partner Countries Successfully Held in Yanqing, Beijing

May 20, 2025Opening Ceremony of the Seminar on Modern Breeding and Management of the Vegetable Industry for BRI Partner Countries Successfully Held in Yanqing, Beijing -

May 18, 2025Sustainable Dairy Development — The 9th International Symposium on Dairy Cow Nutrition and Milk Quality Convenes in Beijing

May 18, 2025Sustainable Dairy Development — The 9th International Symposium on Dairy Cow Nutrition and Milk Quality Convenes in Beijing